Speaker

Description

SNS 2 MW Target Design

Kevin C. Johns

Oak Ridge National Laboratory, Oak Ridge TN

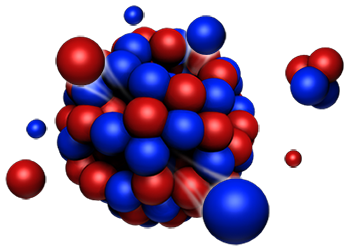

The Spallation Neutron Source (SNS) in Oak Ridge, TN is currently in the preliminary design phase of the Proton Power Upgrade (PPU) which will further advance neutron research at SNS. The upgrade will increase beam power from the current 1.4 MW to 2.0 MW and the beam energy from 1.0 GeV to 1.3 GeV. Reliable neutron production is a facility goal that must be maintained once the upgrades are complete. A key component of the upgrade is the design of the mercury target which must operate for 1250 hours, which equates to four targets per year, before replacement.

The target module operates in a severe environment where conditions such as high radiation, high-cycle fatigue, and cavitation erosion exist. The proton beam also generates a large amount of heat in the target which can lead to high thermal stresses that must be avoided. These conditions create a difficult challenge when designing a target module as they cannot be replicated and tested outside of target operation.

SNS has operated 21 targets to date. Target experience, design improvements, and analysis are being used to develop a target that will meet the operational requirements. Cavitation erosion and high cycle fatigue (giga cycle regime) have proven to be the two limiting factors for extended target operation. Factors such as manufacturability, robust weld design, and remote handling capability must also be accounted for. Although four targets per year is the project requirement, operating this many targets per year is an operational burden and a longer lifetime will be desired.

To date, post irradiation examinations (PIE) has shown gas injection to be effective in mitigating cavitation erosion. Target strain measurements have indicated that gas injection is a viable way to ‘cushion’ the intense pressure pulse which limits the fatigue life of the target. Current targets are limited to about 1 standard liter per minute (SLPM) of helium gas injection per bubbler. The PPU target will build on this recent success by increasing gas injection rates. The PPU target will utilize a swirl bubbler design for small gas bubble injection along with a means to supply a high gas void fraction to the nose of the target where cavitation damage is the most severe. Up to 20SLPM will be achievable with these new features which will require the installation of a gas liquid separator (GLS) that will remove the gas from the mercury loop after it leaves the target.

This presentation will describe the current status of the 2 MW target design and development implemented to achieve a target lifetime of 1250 hours at 2 MW operation.

Johnskc@ornl.gov