Speaker

Description

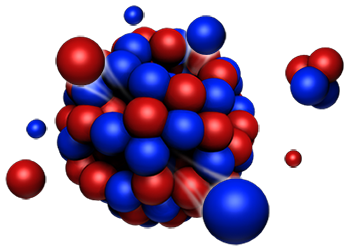

The ISIS Facility at RAL has been producing neutrons for science from the original Target Station (TS1 – 40/50Hz) since 1984. The second, lower power, low-repetition-rate Target Station (TS2 – 10Hz) came on line in 2008.

The TS1 Project currently in preparation will include the complete replacement of the internal parts of the original Target Station, including redesign of the Target, Reflector and Moderators along with all associated cooling systems and services. (ICANS XXII - ISIS TS1 project target Design for manufacture

L Jones / Design and Optimisation of the ISIS TS1 Project Target D Wilcox / ISIS TS1 project summary S Gallimore and M Fletcher) All of this work will be completed in the ISIS shutdown starting in September 2020. One of the first major production milestones was completed earlier this year by assembling the first of the newly designed targets.

The Target Assurance Project was started in 2012; with the aim of bringing the production of Targets in house. Since that time, there has been a great deal learnt from mitigating failure routes. This knowledge has been fed back into the design of targets for both target stations. The production of targets is not a simple process and work is ongoing to develop methods and evaluate new machining technology. Future development plans are now in place focussing on the three main processes; Electron beam welding, Hot Isostatic Pressing (HIP), and Non Destructive Testing (ultra sound techniques). I will discuss the research paths of these technologies and also include the machining procedures including Electric Discharge Manufacture.

Our long-term aim is to achieve total self-sufficiency for target production required for ISIS operations and to set up a programme of knowledge transfer with other related facilities.

In this presentation I will outline the processes that were developed and cover the on-going studies needed to perfect the procedures used in the manufacture of targets at ISIS. Also included are quality assurance reporting and reviewing methods which are constantly being evaluated. I aim to describe the processes used and show the reasoning behind, (and validation of), the decisions that have been made. I will detail our plans to reduce HIP bonding failures to understand how best to increase target life and to develop methods of identifying these critical issues during manufacture. I will also discuss the main challenges faced, how these problems were overcome and highlight the ways in which the team reached a successful solution.